Automated Inspection Systems

Sciotex Automated Inspection Systems

Sciotex is a leader in designing automated inspection systems. Our systems are machine vision based with custom software to solve complex inspection needs. Our machines are designed to operate at the highest speeds possible while maintaining inspection integrity.

Large Parts Inspection System

The Large Parts Inspection System is a conveyor-based automated quality inspection system that detects and classifies four different type defects on multiple sizes of products.

Small Parts Inspection System

The Small Parts Inspection System is a robot-based automated quality inspection system that measures the height, width, diameter, and weight of different types of small parts automatically and precisely.

Surface Defect Detection System

The Surface Defect Detection System is an automated quality inspection system that detects, classifies and grades for different types of defects on reflective surfaces.

Fiber Optic Inspection System

Defect inspection of fiber optic material during manufacturing on a draw tower. This high resolution system uses two line-scan cameras mounted …

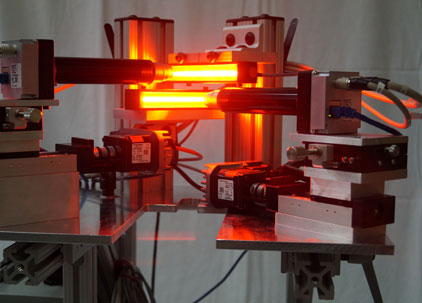

Web Inspection System

The Web Inspection System uses line scan machine vision and proprietary software to detect defects of in wide format, continuous-run manufacturing operations.

In this example, the system is configured to detect defects on long runs of fiber glass strands that are used in the manufacture of large wind turbine blades.

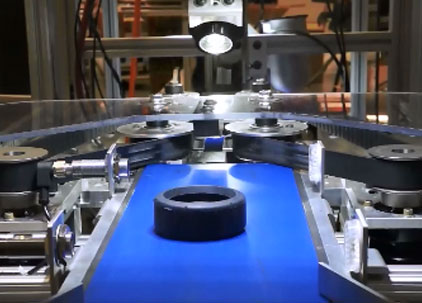

Small Disk Inspection System

The Small Disk Inspection System detects defects on small disk-shaped parts and products like O-Rings, Washers, and other disks on both sides with automated accept and reject systems.

Ball Coleman SeedView Agriculture Seedling Inspection System

Using advanced hardware and software, the Ball Coleman SeedView systems can measure leaf area, seedling height and chlorophyll levels all at the same time!

Automated Gasket Inspection System

The Gasket Automated Inspection System (GIS) automates the inspection of gaskets for defects including excess flash, blisters, tears and under cure.

Extrusion Inspection System

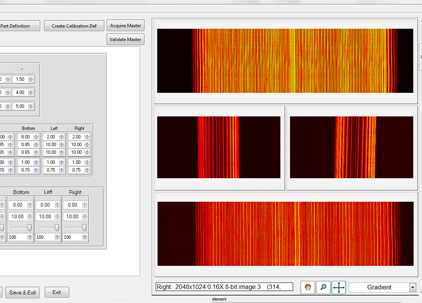

The Extrusion Visual Inspection System (EVIS) automates the inspection and defect analysis of long rectangular extrusions, either as 6 to 8 foot long pieces (offline mode) or as one continuous extrusion (inline mode).

Chip and Wafer Inspection Systems

Sciotex has developed chip and wafer inspection systems for the unique test and inspection criteria for the Semicondustcor Industry.

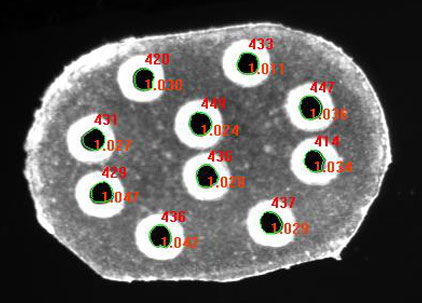

Pharmaceutical Automated Inspection System for Pill Holes

Size and location of multiple laser drilled hole patterns for holes drilled into both sides of medicine tablets which are inspected at a high speed on a conveyor belt.

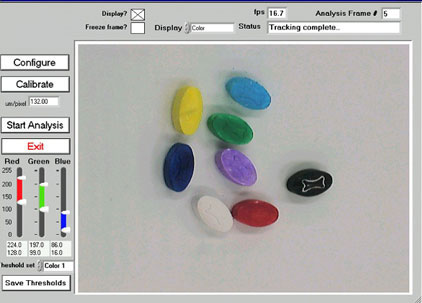

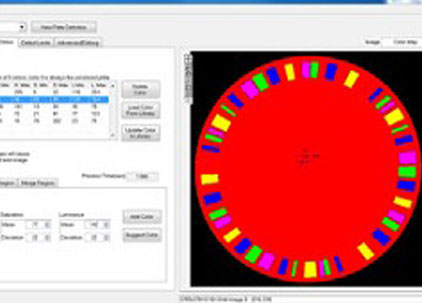

Tablet Coating Monitoring System

Software allows for the tracking of the velocity and exposed area of colored tablets dispersed among white tablets to monitor the mixing process of tablets during manufacturing.

Automated Inspection System for Thin Film Defects

Identifies and quantifies defects in thin films. The system utilizes a high-resolution camera, zoom lens, and XYZ motion control, which allows for imaging over an extended area and for auto-focus control.

Inspection System for Paint and Screen Decoration

Conveyor based system that detects defects in design and pattern of dish ware that is sent through it.

Fiber Optic Component Inspection System

Checks small, glass, hollow core cylinders, used in fiber optic assemblies for a variety of defects, including blocked bore, cracks, and chips.

Mirror Defect Detection System

Quantifies defects on high quality mirrors using laser scattering and high resolution imaging.

Need a Consultation?

Save Time and Money with an Engineered Solution from Sciotex

© Copyright 2023 by Coleman Technologies, Inc. DBA Sciotex