Automated Gasket Inspection System

Gasket Vision System - Gasket Inspection System

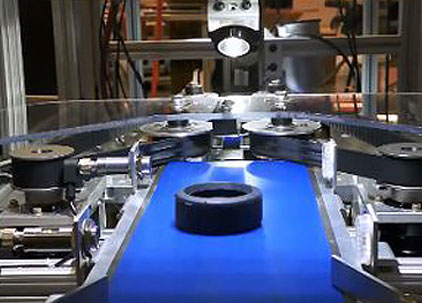

The Gasket Inspection System (GIS) automates the inspection of gaskets for defects including excess flash, blisters, tears and under cure. The GIS quantifies the magnitude of gasket flaws in each part in less than 2 seconds while each gasket is rotated and compressed. The system classifies each part as good or defective and automatically diverts non-conforming gaskets while applying a paint mark to good pieces prior to conveying them out of the system.

Automated Gasket Inspection for Your Specific Needs

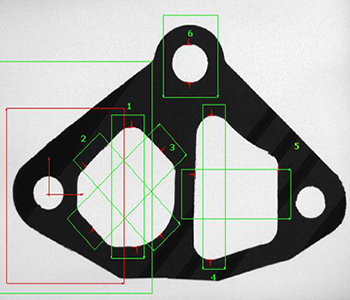

There are a wide variety of gaskets. We can develop custom automated gasket inspection systems to your specific needs. We can detect defects, measurement, metrology and automate the gasket inspection process as little or as much as needed.

In this example, the gasket inspection system is detecting and validating the measurements of the hole sizes.

Gasket Inspection System Demo

This is a fully automated gasket inspection system with a conveyor and automatic accept and reject processing.

Contact us today to discuss your unique situation.

Need a Consultation?

Save Time and Money with an Engineered Solution from Sciotex

© Copyright 2023 by Coleman Technologies, Inc. DBA Sciotex