CONVEYOR INSPECTION SYSTEMS

Conveyor Based Vision Inspection Systems

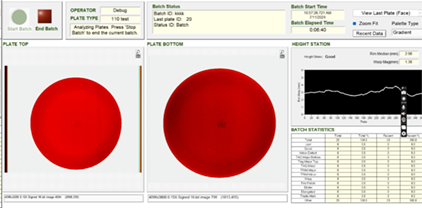

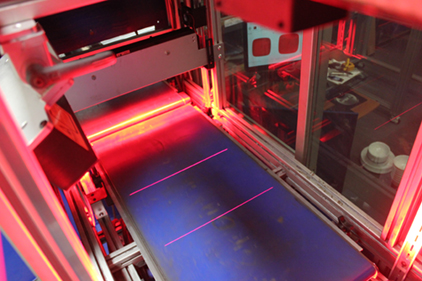

Sciotex, Inc is proud to offer our ConveyorView series of Automated Visual Inspection Systems, which perform high-resolution inspection of both top and bottom surfaces of objects larger than 2 inches wide (51 mm). For objects smaller than 2 inches, we recommend looking at our other automated inspection systems.

As the objects are conveyed through ConveyorView, it passes by customizable imaging substations that can view the sides, top, or bottom of the objects. The bottom of the parts can be inspected by passing over a small gap between two conveyors. Based on the results of the inspection, the objects can be separated or sorted using automated diverters.

Typical Applications

- Defect detection

- Gauging and metrology

- Optical Character Recognition (OCR) & OCV

- 3D laser height mapping

Standard Configuration

- 12 inch wide by 3 foot long conveyors (1 inlet, 1 outlet), speeds 0 to 150 feet/min.

- Two 4k camera systems : < 0.003” resolution of both top and bottom surfaces

- LED line illumination

- PLC compatible digital output of inspection results

- Custom modified, application specific, ConveyorVIEW Inspection Software

- Proprietary imaging analysis software built by Sciotex

Common Options

- Single conveyor with top and/or bottom inspection

- 3D laser height mapping

- Remote monitoring & result communication via TCP/IP

- Additional imaging stations

- Laser line illumination

- Touch-screen monitor

- Fully customized to meet your inspection criteria

- AI and traditional high-speed imaging analysis software built by Sciotex

Contact Sciotex today to talk about your inspection needs.

Need a Consultation?

Save Time and Money with an Engineered Solution from Sciotex

© Copyright 2025 by Coleman Technologies, Inc. DBA Sciotex