Process Control Applications

Process Control Systems and Software

Sciotex provides process control software development services and has the experience of developing numerous process control applications for large chemical and industrial process automation systems. In fact, we’ve been doing it for so long that we’ve developed our own framework. This offers our clients a big head-start on their projects and can save time. From pilot plants to full production… Contact us to discuss your project!

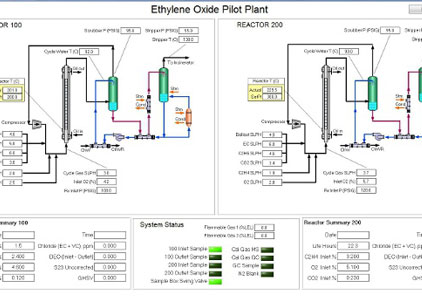

Ethylene Oxide Reactor

Compact FieldPoint Real-Time process control and monitoring application for an EO pilot plant.

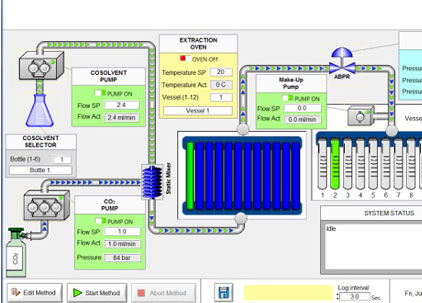

Watlow & Eurotherm Reactor Systems

Sciotex has developed numerous small reactor systems utilizing Watlow and Eurotherm controllers to control temperature, pressure, flow, and other parameters.

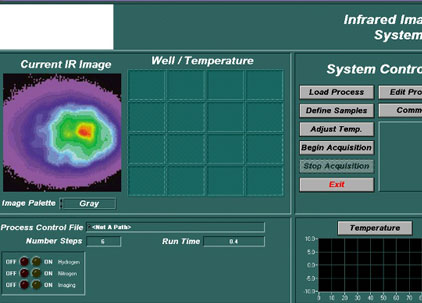

Bio-Sample IR Analyzer

System with IR camera monitoring small temp changes in wellplates. System also controls gas mixture and pressure exposed to samples.

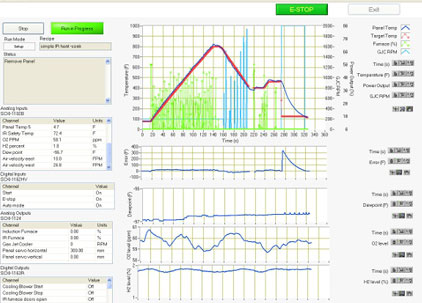

Hot Dip Simulator

Controls motion, heating, cooling and logs data from a 1/10th scale simulator of steel manufacturing facility. Uses PID control to optimize heating and cooling of steel panels.

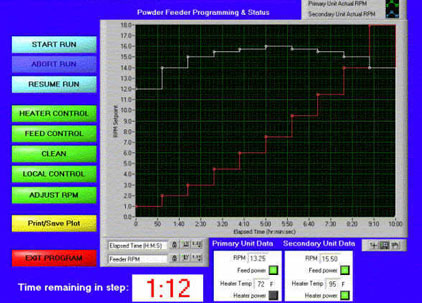

Powder Feed Control System

Controls the powder dispensing rate, heater temperature, and other functions of one or two powder feed controllers.

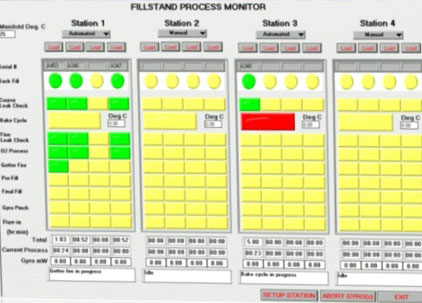

Fillstand Control System

Controls the filling and testing of ring laser gyroscopes. Allows for the simultaneous processing of 16 gyros.

HFC Refrigerants Reactor

Sciotex has developed multiple custom software applications to control and monitor HFC refrigerant reactor pilot plants. These high channel count systems employ NI cFP Real-Time hardware for the highest level of reliability.

Photocell Production System

Controls the manufacture of photocells in a vacuum chamber. User can create, edit, and load recipes which control temperatures, times, and gas pressures of various process phases.

Semiconductor Deposition System

Controls a vacuum deposition system used in producing optoelectronics. The control software controls the deposition parameters via recipes, the vacuum system, and residual gas analyzer.

Electroplating Control System

Controls the electroplating process for semiconductor materials in a system that is easily expandable to include multiple electroplating tanks using just one computer to control the various electroplating stations.

Need a Consultation?

Save Time and Money with a Process Control Solution from Sciotex

© Copyright 2025 by Coleman Technologies, Inc. DBA Sciotex