Automated Extrusion Inspection System

Extrusion Visual Inspection Systems

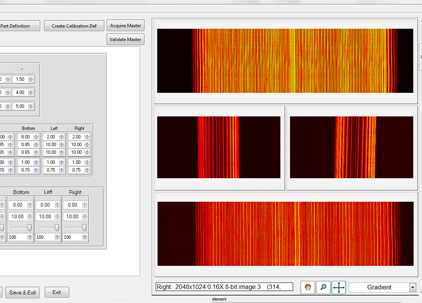

The Extrusion Visual Inspection System (EVIS) automates the inspection and defect analysis of long rectangular extrusions, either as 6 to 8 foot long pieces (offline mode) or as one continuous extrusion (inline mode). The EVIS quantifies the magnitude of extrusion flaws in each part that is inspected. The system classifies each part as good, minor defect or major defect and in offline mode automatically sorts output pieces based on the classification. Part width, height and length are also measured for compliance. In inline mode the extrusion is continuously monitored for manufacturing flaws. Inline mode provides a mechanism for cutting parts to a specified length and detected defects are automatically cut out to short lengths for recycling in the extrusion process.

The program has a graphical user interface which is designed to be intuitive to use. The software provides prompts and guidance through the use of pop-up dialogs and tool-tip messages. The user needs no specialized knowledge to run the system successfully.

Four cameras (Top, Bottom, Left, Right) and two light sources are used to illuminate an area around the part and scan 4000 lines per second to capture the image.

Contact us today to discuss your unique situation.

Need a Consultation?

Save Time and Money with an Engineered Solution from Sciotex

© Copyright 2023 by Coleman Technologies, Inc. DBA Sciotex